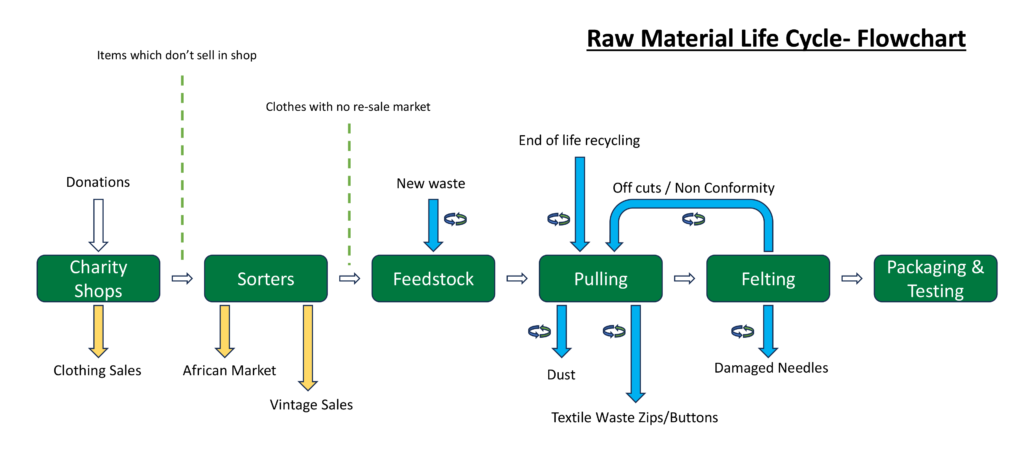

Product Life Cycle – Mixed Fibre Needled Felt – July 2023

Charity shops

The main source of the clothing are charity shops and rag banks. Here unwanted cloths are deposited by members of the public and any items that can’t be sold in the shops are bagged and sent to rag sorters. The shops will sell the rags to sorters thereby receiving an income for their respective charities.

Sorters

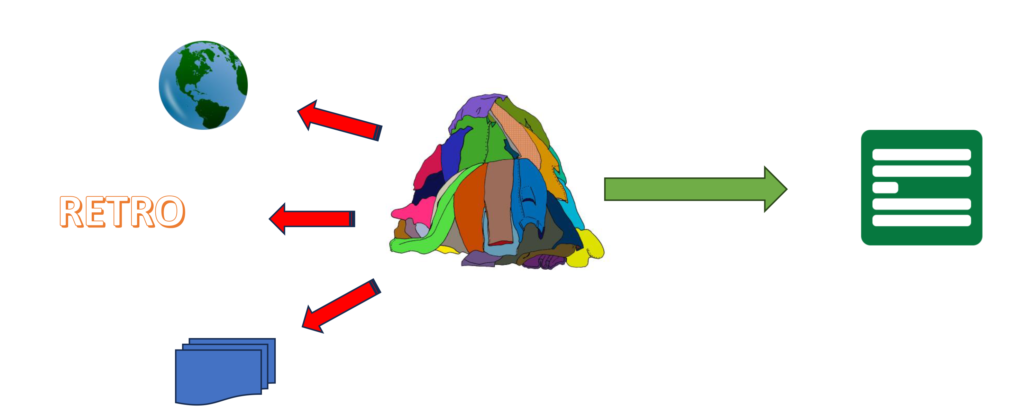

Sorters buy charity shop rags which are delivered in plastic bags of mixed items. (Known as original clothing)

The sorters (or rag merchants) will grade the items into a huge array of types to sell to markets for reuse. T shirts, light weight ladies dresses, shoes, bras and a wide variety of other types are sold to African countries, and other items such as retro wear are sold in the UK or Europe. There are also markets for wiping rags (Cotton shirts) and shaded knitwear for further mechanical processing. Our feedstock comes from the items which have no use in these markets.

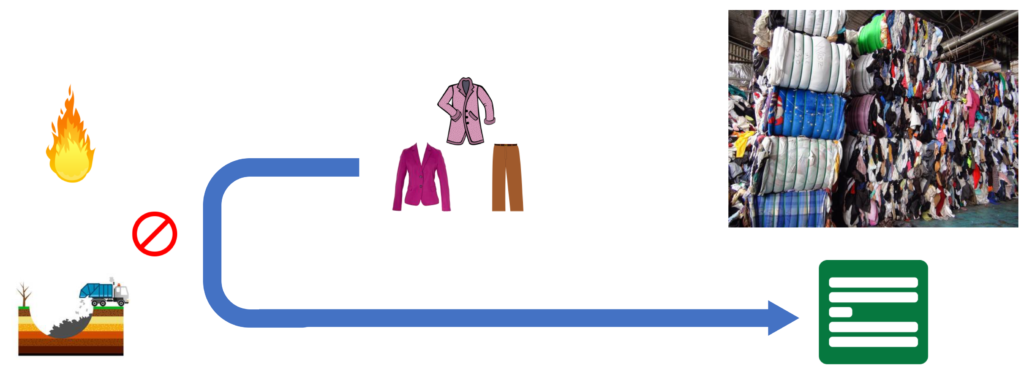

Our Feedstock

These items are typically heavy overcoats, jackets and trousers, worn out or damaged pieces of clothing. These would be landfilled or sent to energy from waste if the flock industry didn’t exist.

Sorters bale the grades we require into large 350 – 400 kgs bales and transport them to our mill. The price we pay covers the transport costs and avoids sorters paying landfill charges and taxes.

We can also supplement our feedstock with “new waste” which are offcuts from the general textile trade. These would include selvedge edge trim and clips from cloth cutting. Carpet thread waste can also be used. (Typically 80/20 wool / nylon blends)

Pulling

Pulling, as opposed to shredding, transforms garments back to their fibrous state. Fibres are pulled out of their weave or knit to made flock.

During the pulling process the textile items are gradually broken down to fibre whilst at the same time metal, plastic buttons etc are removed.

The waste metal is baled and sold for further refinement, where metals and other items are extracted for further processing.

Dust from the pulling process is also reused for cattle bedding or rhubarb growing!

After pulling flock is baled for the next felting stage of the process.

Felting

Our felting process is mechanical as opposed to thermal bonding.

Thermal bonding uses polyester melt fibres to stick the fibres together, using excessive amounts of gas and virgin man-made fibres.

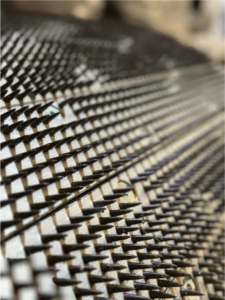

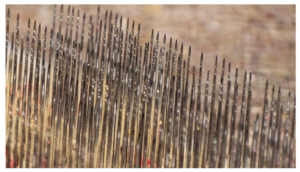

Mechanical bonding uses a needle loom, whereby barbed needles pass through the felt

interlocking the fibres together. (No additional binder fibres or gas is required)

Before the loom the fibres are orientated into a web using an Airlay machine. This forms a web of material which passes through the loom for the needling process.

After the loom the finished felt can be slit and guillotined into a variety of sizes for the end

customer

Packaging

There are a number of packaging systems available, but here we prefer our own in house manufactured steel cages which whilst protecting the felt inside, can be returned and reused countless times and cut the requirement for manual handing of the end product. The unique cage

design enables them to be nested when empty (Reducing transport costs) and stacked when in use (Reducing warehouse space).

Testing

Our felts are required to pass vigorous tests for both Fire Retardancy and Cleanliness.

These are mattress and upholstery tests which by the very nature of the end product have to be strictly adhered to.

UK2101106-2 Needled Felt Sch2 Pt1 Source 2 <<<<<<<<<<< Video Link

The cleanliness test is BS:1425 and tests for any traces of bacteria in the sample.